The processing

The milling

The VABRO and BOURBON DEL MONTE extra virgin olive oil is a 100% Italian oil obtained from native olives, such as Frantoio, Leccino, Pendolino, Moraiolo. The olives are harvested by hand and cold pressed within 24 hours of collection. The milling takes place with a new generation machinery, at a temperature below 27°C which allows the original characteristics and nutritional values of the olives to remain unaltered.

WHATCH THE VIDEO

THE STAGES OF PROCESSING

First, the olives are ventilated to remove twigs and leaves, after which they are thoroughly washed in cold running water to remove dirt and foreign bodies.

The olives are then passed on vibrating grates to remove excess water.

Inside the hammer crusher, he olives are crushed to obtain a coarse paste containing peel, pulp and stones which have a draining function and facilitate the subsequent separation of the oil from the dough.

Thanks to the use of the hammer crusher it is possible to crush a large quantity of olives quickly, obtaining a more uniform paste and limiting to a minimum the harmful contact of the olive paste with oxygen.

The olive paste is gently stirred for about 30 minutes in heated tanks at a temperature below 27 °C to allow the oil particles to aggregate.

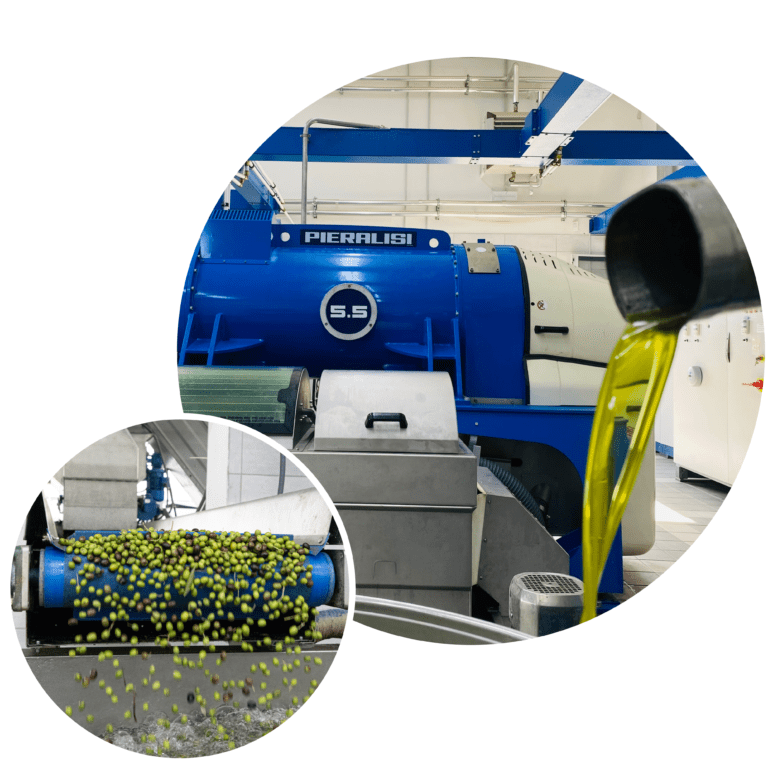

The resulting paste then passes through the extractor where, thanks to the centrifuging system that interacts on the different specific weight of the components, two-stage separation of the solid part (grassy and vegetative water) with the liquid one is carried out (oily must and water of vegetation).

The crude oil obtained from the extractor is subjected to a further passage inside a separator that will free the product of residual water and impurities.

The oil that comes out is extra virgin and ready to be consumed.

Extra virgin olive oil is stored in stainless steel containers under nitrogen pressure in a temperature controlled environment between 15° and 21°C.

The packaging is carried out by specific equipment (such as automatic or semi-automatic bottling machine) that allow the oil to be poured into specific containers.

Once bottled, the container is hermetically closed to avoid any alteration of the organoleptic properties of the oil and immediately after it is sealed, labelled and boxed.